Felt compaction vs contamination: do you know the difference?

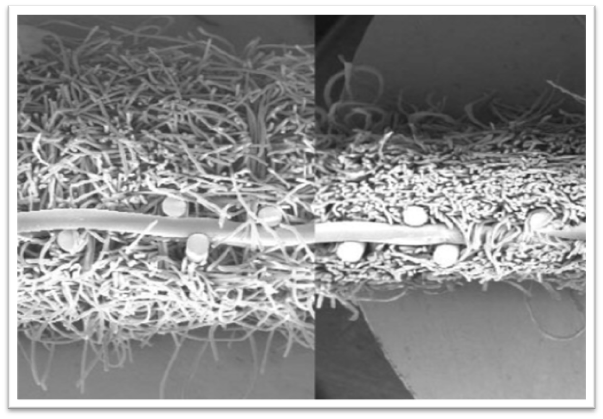

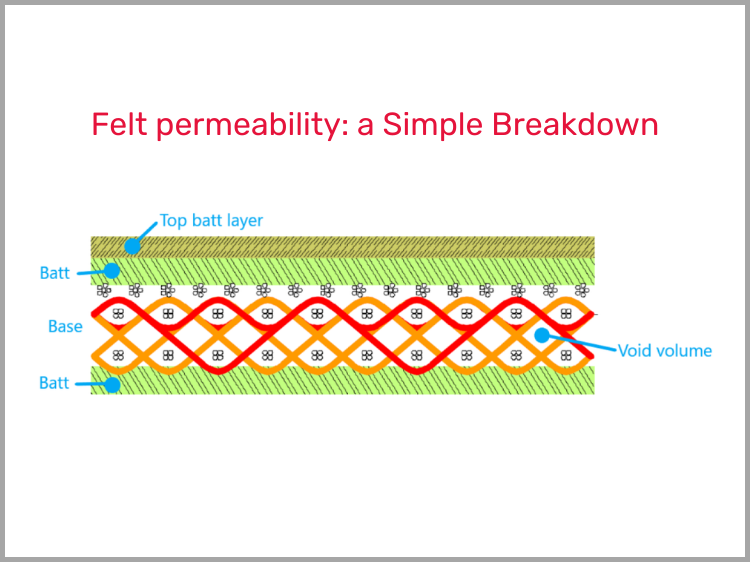

After you install a new felt, it's normal for its dynamic permeability (the combination of airflow and vacuum) to fall. This means the felt is compacting. However, contamination will also make it denser.

To distinguish between these two possible causes for a denser felt, you need to take the felt caliper into account. And the only way to get an accurate point of reference—knowing whether the felt is ‘relatively thick’ or ‘relatively thin’ today compared to previous days—is to take daily measurements.

The combination of three tests—vacuum, airflow, and caliper—provides valuable information on your felt’s overall condition, as seen in the table on the right.

Adjusting felts while the machine is running

Unfortunately, there are limited ways to adjust unfavorable felt permeability.

If a felt is dense but not too compacted, thorough felt washing makes sense. But on the other hand, when the felt is both dense and compacted, installing a new felt may prove more cost effective.

For open felts, the options are also limited. When felts are open because they are worn, they need to be replaced as soon as possible. When a felt is too open and yet still bulky, it’s probably still in its break-in period. This situation can be improved by trying to compact the felt, for example, by increasing the press load or introducing more water into the nip (by switching off one Uhle box).

Finding a compromise

Permeability is always a compromise between dewatering and re-wetting. But the CFM value on the felt’s datasheet is of no value to the paper manufacturer.

Typically, felts for nip dewatering are denser than for Uhle dewatering, but that is about the only rule-of-thumb for felt permeability.

This is why it’s important to understand your ‘normal’ felt permeability, so you can detect deviations and react in time. And this brings us back to the test results from airflow measurement, vacuum, and felt caliper—a combination of the three will give you an excellent indication of your felt’s condition. Something that’s only possible through daily data.

The Permeability Package:

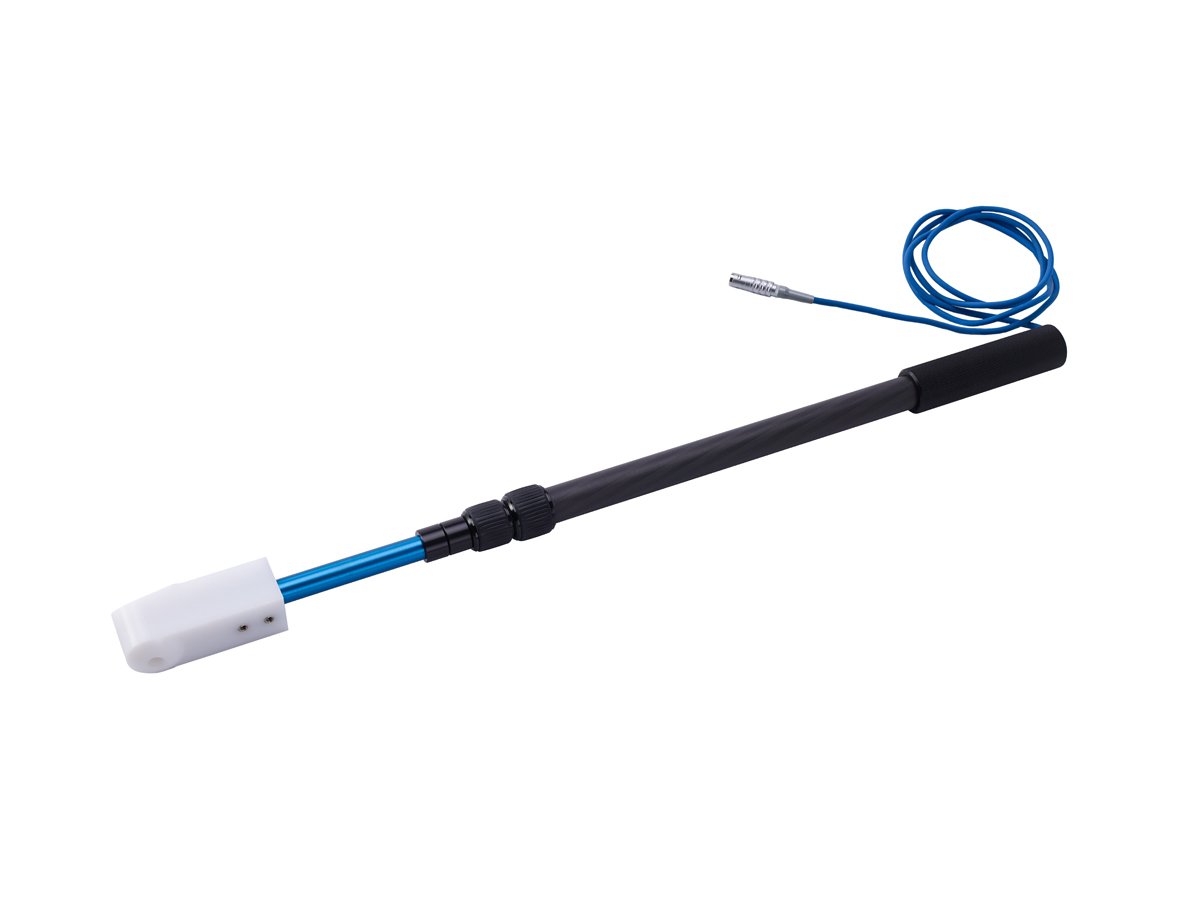

The combination of the Caliper Profiler, AirSpeed Sensor and the RealVac will give you an excellent indication of your felt’s condition.

The Caliper Profiler measures the true fabric caliper, not influenced by a water film or small contaminations on the fabric’s surface. Due to the profile function you will always detect the minimum caliper within 30cm/1 foot from the edges.

Prices are in US $

It’s good practice to monitor the press felt condition on a daily basis. The Feltest AirSpeed Sensor helps you better plan your machine downtime, use the right amount of felt cleaning agents, and troubleshoot any performance problems.

Note: the TrueSpeed Sensor needs to be combined with a Feltest SpeedController (not included).

Prices are in US $

Measure the vacuum where it matters: inside the uhle box. Simply slide the RealVac under the felt into the slit of the uhle box.

Prices are in US $