5 things to look for when choosing a new machine clothing supplier

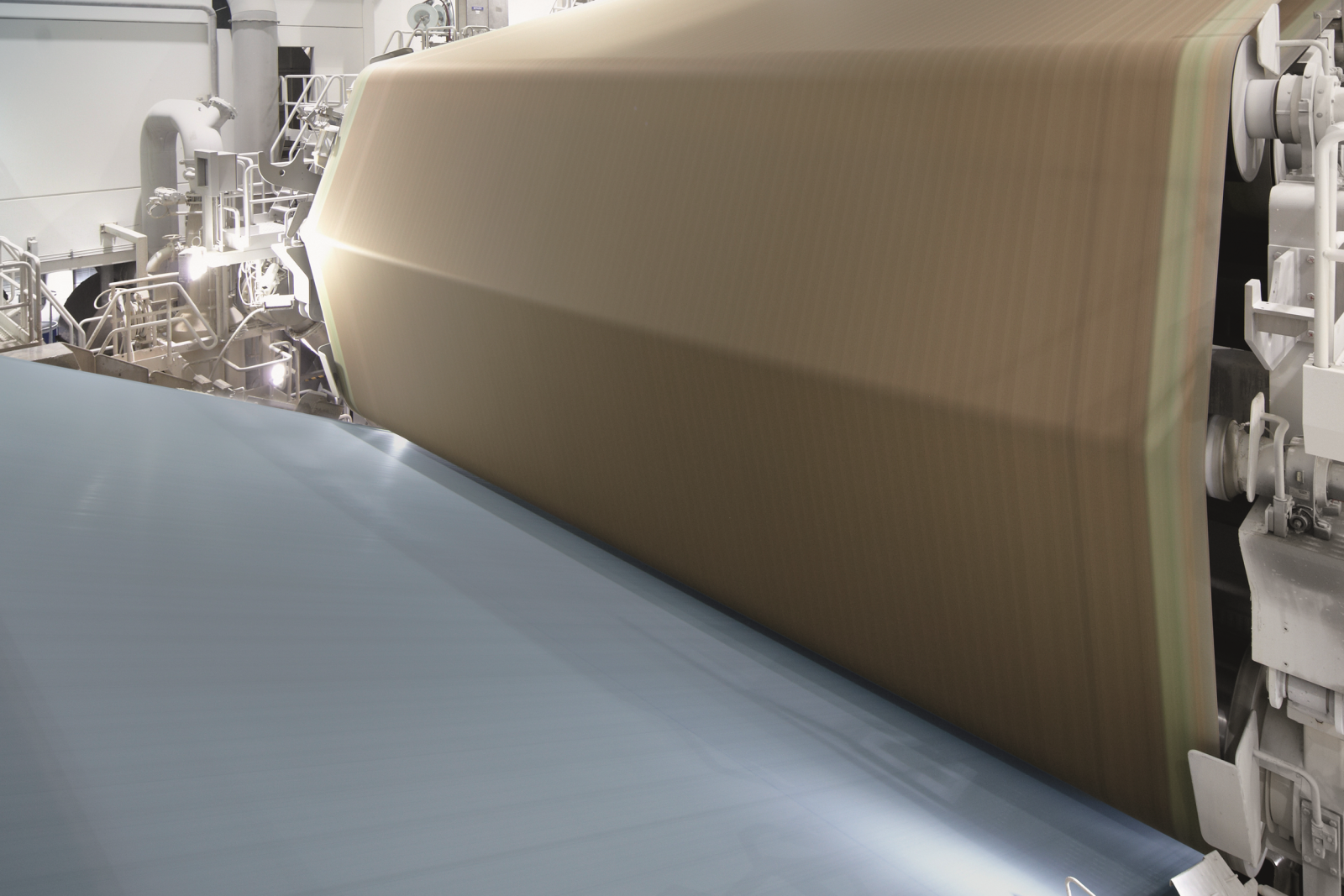

As a papermaker, the relationship with your machine clothing supplier is critical to the performance of your mill. Yet many mills still rely on a single supplier, leaving themselves exposed to potential issues.

Here are 5 characteristics to look for when selecting a new or additional paper machine clothing supplier: