- Home

- Products

- TensioMaster

- Feltest TensioMaster

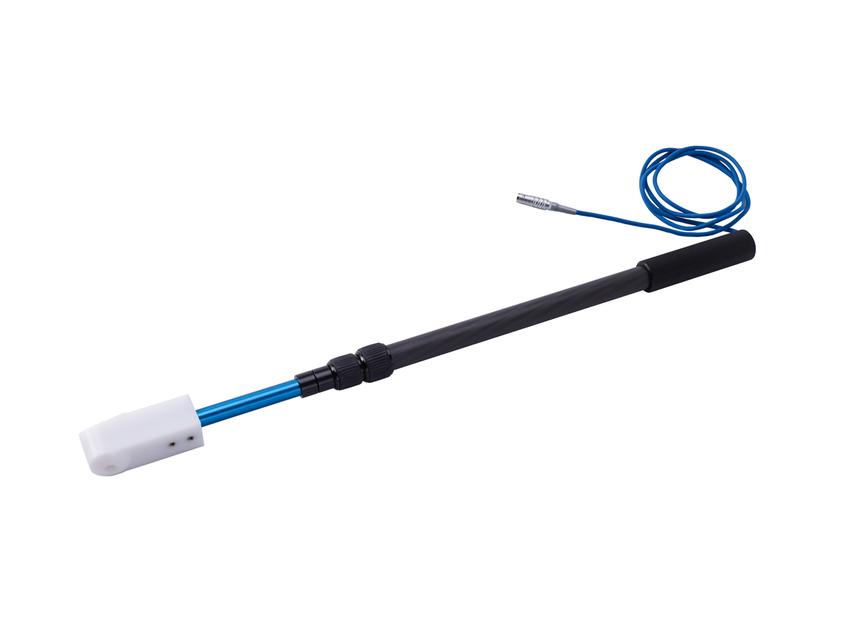

Feltest TensioMaster

CORRECT TENSION = BETTER RUNNABILITY

Paper Machine Clothing tension affects dewatering, sheet properties, guiding, wear and total machine runnability. The ruggedly built Feltest TensioMaster is a compact precision instrument that measures the tension in running forming fabrics, press felts and dryer screens.

Suitable for forming, press and dryer fabrics

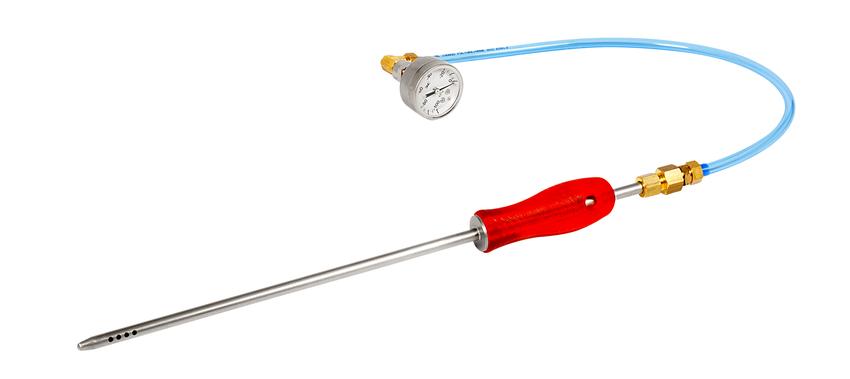

The travel of the sensing element is converted into fabric tension, as indicated on the calibrated dial. The maximum reading is held by a sliding pointer which can be easily reset. Accurate readings can therefore be taken in a safe way, even in dark places or difficult to reach areas.

Better runnability

Paper Machine Clothing running at an in-correct tension will have a negative effect on the machine’s runnability. Too low tension decreases the fabric’s stability, resulting in wrinkles and unplanned fabric changes. Too high fabric tension influences the fabric mesh and changes the dewatering behavior.

Fill in the form and download the brochure

Paper Machine Clothing running at an in-correct tension will have a negative effect on the machine’s runnability. Too low tension decreases the fabric’s stability, resulting in wrinkles and unplanned fabric changes. Too high fabric tension influences the fabric mesh and changes the dewatering behavior.

FAQ's

Paper Machine Clothing running at an in-correct tension will have a negative effect on the machine’s runnability. Too low tension decreases the fabric’s stability, resulting in wrinkles and unplanned fabric changes.

Please check out the instruction video on the right. First, gently touch the fabric with one (short) edge of the instrument. Then rotate your wrist so the other (short) edge touches the fabric too. After both edges simultaneously touch the fabric, immediately move the instrument off the fabric. The TensioMaster’s drag pointer will hold the highest reading for you, so you can read the dial outside the machine’s run.

Yes, the measured values will appear lower because of the worn-out bar. Check out our whitepaper for more information.

Do not place the TensioMaster on the measuring bar at the bottom: this may damage the internal clockwork.

Place it back in its case when you are finished or put it gently on its side like the picture below:

It can be used on running forming fabrics, press felts and dryer screens.

If tension is too low, it causes wrinkles, slippage, and unplanned fabric changes. Too high fabric tension influences the fabric mesh and changes the dewatering behavior. And any uneven tension will guide the fabric to one side, requiring ongoing counter-steering.

“Felt and wire tension is extremely important especially for drainage. I always endorse this to people.”

— RICHIE G. (UK)

“Felt and wire tension is extremely important especially for drainage. I always endorse this to people.”

— RICHIE G. (UK)

“Felt and wire tension is extremely important especially for drainage. I always endorse this to people.”

— RICHIE G. (UK)

| Specifications | Tensiomaster |

|---|---|

| Measuring principle | Measuring travel on a predetermined spring load |

| Measuring range | 0.5 - 20 N/mm (2.9 - 114 pli, conversion table included) |

| Suitable for | Forming fabrics, press felts, dryer screens |

| Safety features | One-hand operation. Measures in any position. Sliding pointer mechanism. |

| Protection | IP 64 (splash water proof) |

| Dimensions | 203 x 140 x 210 mm | 9.1 x 5.5 x 8.3 in |

| Weight | 1.16 kg | 2.56 lb |

Get your TensioMaster Quote

Get your quote instantly by adding it to your shopping basket and pressing the Request Quote button, or buy directly in our ONLINE STORE.

Any questions? Just reach out and our sales team will contact you shortly.