Products

Are you tired of production interruptions and quality issues? Is Paper Machine Clothing (PMC) more than once to blame?

Start saving time and money and avoid frustration with our powerful handheld tools for assessing and optimizing the runnability of your Paper Machine Clothing.

You don’t have to wait for a PMC supplier to show up, you can start now! As our products have payback times in minutes, rather than hours, you have no time to lose.

Scroll down to see a total overview of our products, or click on one of the links to go directly to a product page.

Capto

TensioMaster

SpeedController

TrueSpeed Sensor

AirSpeed Sensor

RealVac

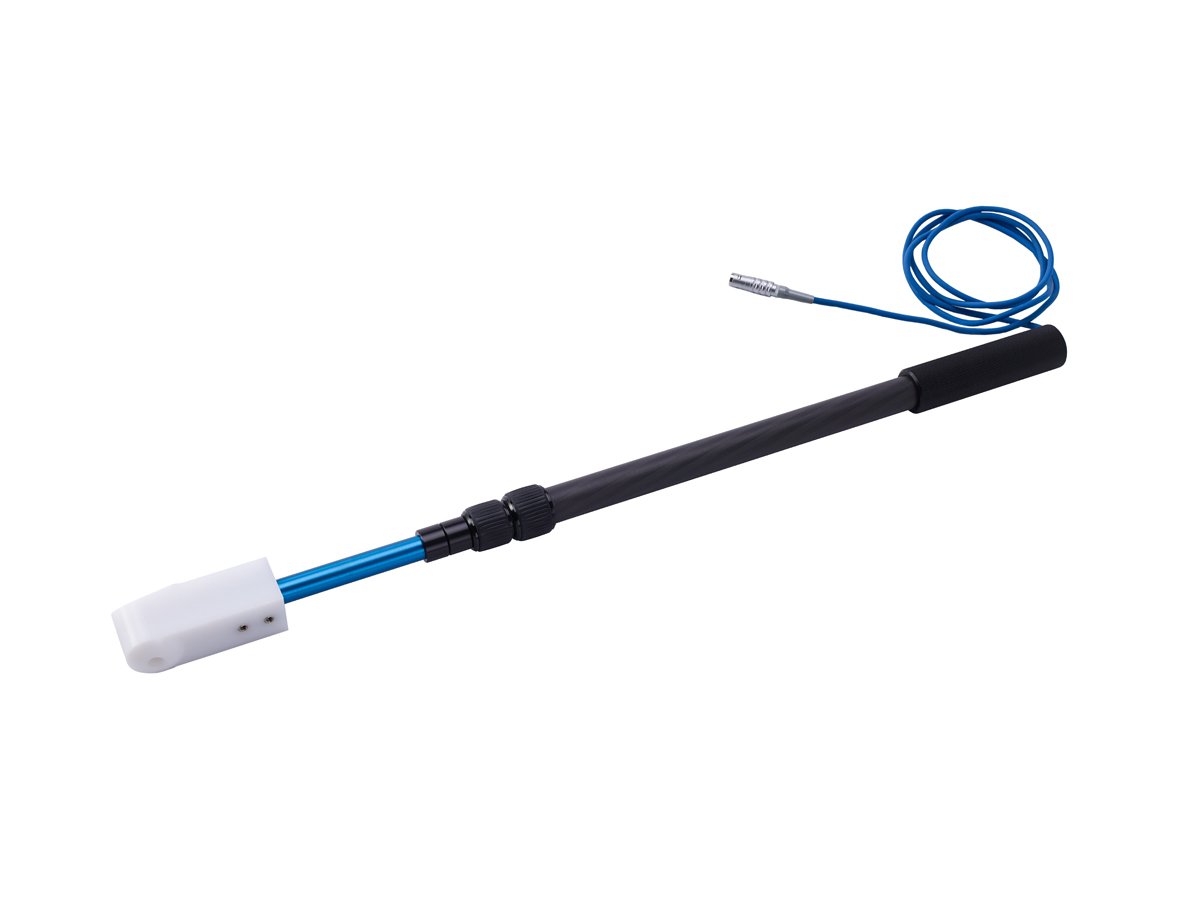

Caliper Profiler

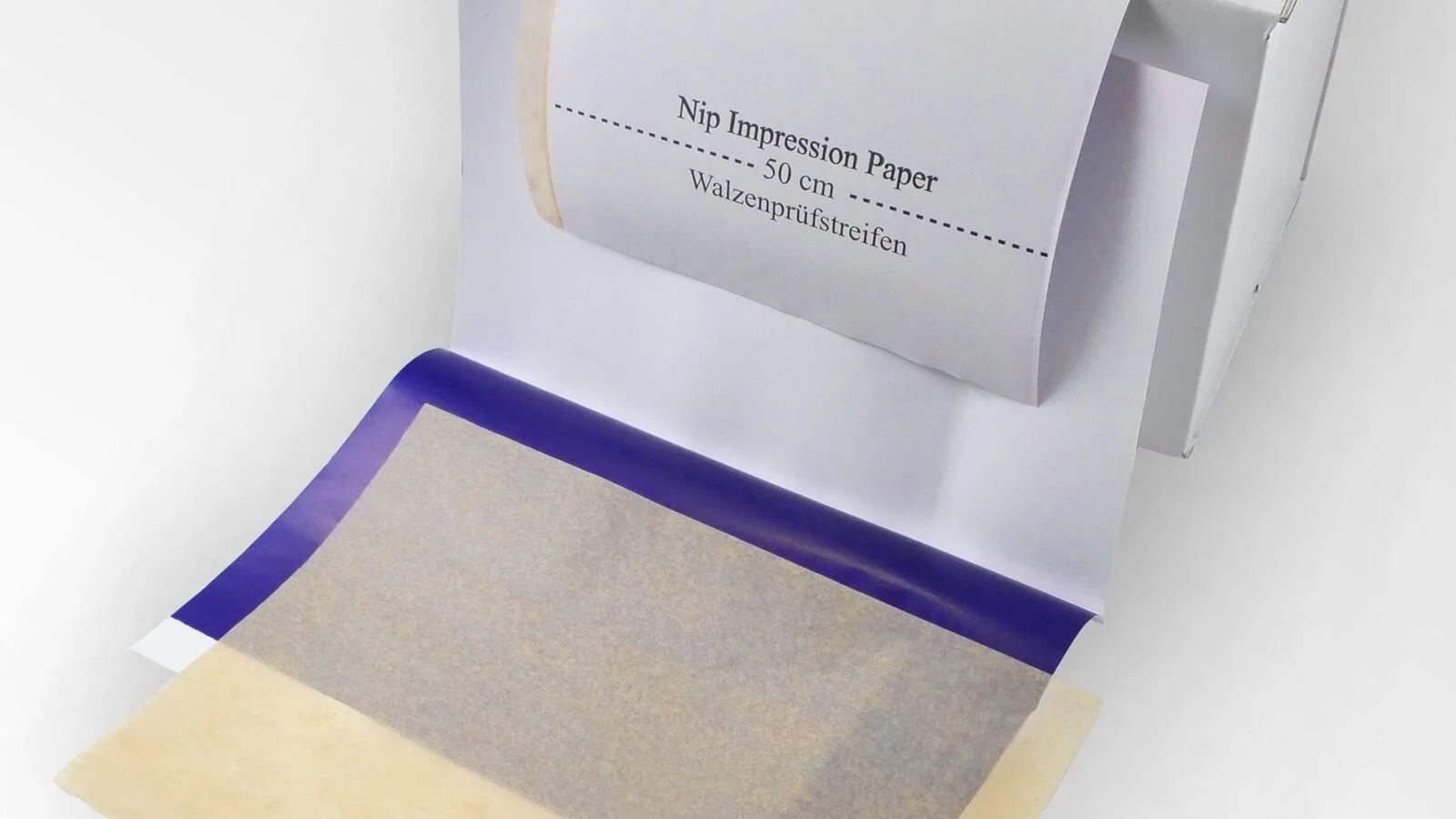

Carbon paper

Fujifilm for nip impressions

PocketStrobe LED

FiberScanOne

Upcoming: TensioPlus & Aequo