How a mill took advantage of PMC trials

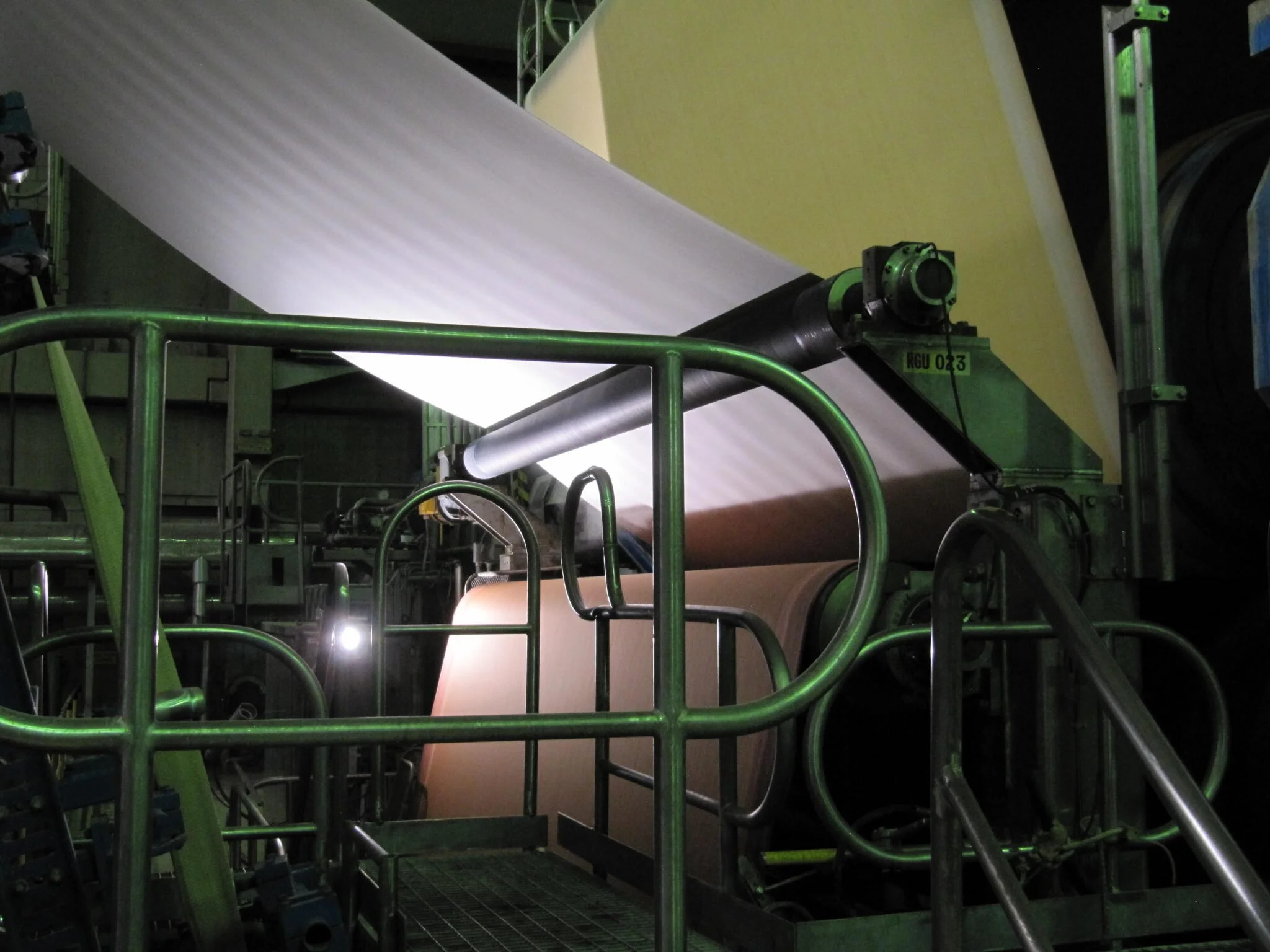

Where PMC trial theory meets practice… this is a case study about improving felt performance in a 200″ wide machine in a European paper mill.

This article is the follow-up on the previous article about how to maximize pmc value with this innovative mindset.

Context And Background

This graphic paper machine was designed and erected in the 1960s. After several upgrades over the decades it is running at 3750 fpm, approximately 150% of its original design (!) speed.

PMC supplier A is the sole supplier for all four press positions and has been for the past eight years. The problems (for pessimists) or the opportunities for improvement (for realists):

• The 4th press is extremely vibration prone

• Press felts last only 2 weeks

• The venta nip press roll cover lasted only 4 weeks

• The granite press roll shows unusual and excessive wear.

For eight years the vibration problem of the 4th press only gets bigger, but the felt supplier A never manages to find a solution. Meanwhile supplier A continues to supply about four tons of press felt a year for the 4th press position alone. Supplier A is not complaining.

The Trial

The production manager is fed up with this situation and invites three other PMC suppliers to analyze the situation and suggest a solution. PMC supplier B performs about four service measurements, suggests a different press felt design and gets a trial order, which fails hopelessly. Supplier B is not given a second chance due to their poor preparation and inadequate explanation of why their trial failed.

PMC supplier C invests in a series of sixteen service measurements to catch ‘the normal’ of this machine. This means sixteen 8-hour days for a senior Service Engineer who investigates the entire press section under many different circumstances – quite an investment for supplier C who had no previous sales volume and no guarantee they would get any orders now.

The first trial of supplier C achieves the standard lifetime with fewer problems than ‘house’ supplier A. Based on this first result, the production manager decides to continue trials with supplier C while he carefully monitors his main KPI: machine speed reductions due to 4th press vibrations.

A few months after the initial trial, trial felt number 4 is the first felt that safely achieves a running time of four weeks. After that a redesign of the synthetic press roll cover by its supplier contributed to an additional significant reduction in vibrations.

Fast forward another nine months and we see a major reproducible success. The 4th press easily achieves a lifetime of six weeks with an outlook towards nine weeks.

Due to the trial results, this paper mill can permanently change its paper machine maintenance shutdown cycle from two weeks to three weeks.

Savings In Detail

The planned number of 4th press felts goes down from 26 to 9, saving 17 pieces per year. The number of times the 4th press bottom roll needs to be grinded goes down from 12 times to only 1 (one!) time per year.

Due to the new 3-week cycle, the number of maintenance shutdowns goes down from 26 to 18, bringing 8 x ≈8h = 64 additional production hours per year.

Although the actual output data are not disclosed, the machine produces a lot more due to a higher average speed on the heavier paper grades and more grades running at the machine’s (dryer limited) top speed.

See The Whole Picture

Obviously fantastic results come at a price. Over the approx. 12 month trial period:

2 trial felts fail dramatically, one each for supplier B and C.

4 trials do not achieve their planned lifetime and must be taken out prematurely.

Monitoring of trials and discussions with the suppliers take up a lot of time and attention of the production manager.

And ongoing: the ‘winning’ 4th press felts are about 20% a piece more expensive.

But with a proven increase of lifetime of 200%, who is complaining? Supplier A, maybe? Well, don’t underestimate the power of truly unexpected side effects, because this is what happens next:

Supplier A loses the 4th press position, BUT -undoubtedly stimulated by seeing the results of supplier C- they miraculously manage to improve the performance of their pickup and 3rd press felts, bringing the mill even more financial benefits.

The Human Factor

And last but not least, let’s not rule out the human factor in running successful machine clothing trials.

The production manager for this mill was focused, persistent and data driven. He set new goals step by step. He was heard having ‘loud discussions’ with mill management. He took calculated risks, stood out, resisted the pressure from conservative members of management, and in a few years he saved his company millions of dollars.

Initiating and sticking with structured and disciplined trials paid out big time for this paper mill.

No risk, no future

As an independent supplier, Feltest strongly believes that innovative trials with machine clothing secures the future of the Paper Industry. Let us know what else you think you need from us to get started. Also, if you would like us to feature your PMC trial in our newsletter, contact us for an interview.

If you have any questions left, or if you want to share your opinion, feel free to contact me or my Feltest team at info@feltest.com.

So remember DDPP - Daily Data Powers Production.

Toward better Paper Machine Clothing,

Marcel